5 Types of Earthing: Advantages of Earthing

The types of earthing are used to connect the metallic parts of an Electric appliance or installations to the earth and the earthing is provided to avoid or minimize the danger of electrocution.

Through low resistance wires or electrical cables earthing is the method of transmitting the instant electricity discharge directly to the ground and to keep away from the danger of electric shock due to the outflow of current then earthing is provided.

The process of earthing can be done in several ways like wiring in factories, housing, other machines, and electrical equipment and there are many types of earthing such as plate earthing system, rod earthing system, and pipe earthing system, etc.

Types of Earthing:

There are five main types of earthing as given below;

- Plate Earthing System

- Pipe Earthing System

- Rod Earthing System

- Earthing through the Waterman

- Strip or Wire Earthing

Plate Earthing System:

In these types of earthing a plate is made up of copper or galvanized iron which is placed vertically in the ground pit less than 3 meters from the ground and one should maintain the earth moisture condition around the plate earthing system for a better electrical grounding system.

To divert the electric charge inside the earth this plate is connected to the electrical conductors.

Pipe Earthing System:

In pipe earthing system a galvanized steel-based pipe is placed vertically in a wet and it is one of the most common types of earthing.

On the soil type and magnitude of current, the pipe size mainly depends and the pipe dimension should be 1.5 inches in diameter and 9 feet in length for the ordinary soil. The pipe diameter should be greater than the ordinary soil pipe for rocky or dry soil and soil moisture will choose the pipe’s length to be placed in the earth.

The galvanized iron pipe should be such that it has holes pierced at regular intervals and at the bottom end, the pipe should be narrow. To galvanized iron pipe a clamp is attached to which an earth wire is connected and inside the earth, this pipe diverts the electrical conductance.

At a depth not less than 3 meters the pipe is placed in the earth pit and by the alternate layers of salt and charcoal, the space inside the galvanized iron pipe is filled up to the clamp level.

By constructing a chamber with bricks, the top portion of the G.I pipe is left open for maintenance when required and to maintain earthing resistance within the specified limits water is poured into the galvanized iron pipe.

For all domestic purposes, pipe earthing is commonly used and it has low-cost.

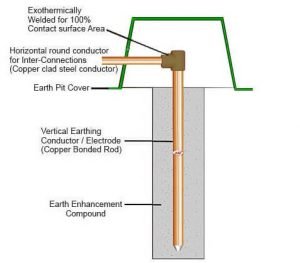

Rod Earthing System:

In these types of earthing a copper rod with galvanized steel pipe is placed upright in the ground physically or by using a hammer and to a preferred value, the lengths of the embedded electrodes in the earth decrease the resistance of earth.

At a certain depth, the rod used for this purpose is buried inside the earth and safely the short circuit current will be diverted to the ground.

For areas which are sandy in character, this system of earthing is suitable and this system of earthing is very cheap.

Earthing through the Waterman:

The waterman (Galvanized GI) pipes are used for earthing purposes in these types of earthing and to minimize the resistance for proper earthing connection make sure to check the resistance of galvanized iron pipes and use earthing clamps.

As earth wire, if the stranded conductor is used then clean the end of the strands of the wire and make sure it is in the straight and parallel position to connect tightly to the waterman pipe.

Strip or Wire Earthing:

In these types of earthing, strip electrodes of cross-section not less than 25 mm x 1.6 mm is buried in horizontal trenches of a minimum depth of 0.5 m and if it is a galvanized iron or steel then their cross-section area should not be too small as less than 6.0 mm2.

The length of the conductor should not be less than 15 m and this length buried in the ground would give a sufficient earth resistance.

Advantages of Earthing:

There are the following advantages of earthing such as;

- From the shortcircuit current, the earthing protects the personnel.

- To the flow of shortcircuit current even after the failure of the insulation the earthing provides the easiest path.

- From the high voltage surges and lightning discharge, the earthing protects the apparatus and personnel.

- The earthing helps to detect any fault in neutral conductors and phase.

- It gives the surge protection and also gives protection against electrical shock.

- During insulation fault, earthing also helps to eliminate the risk of fire or explosion.