6 Types of Bearings and Their Advantages

There are many types of bearings for different purposes and bearing is a device that is used to enable rotational or linear movement while handling stress and reducing friction.

There are many types of bearings as discussed below;

- Plain Bearings

- Ball Bearings

- Roller Bearings

- Fluid Bearings

- Magnetic Bearings

- Flexure Bearing

Plain Bearings:

These bearings are one of the most basic types of bearings and consist of a flat surface without any rollers or balls. These bearings have much longer lives than other types and have a high load-carrying capacity and generally the least expensive.

To reduce friction, plain bearings like flat wheels, and like other bearings are placed between two surfaces. For sliding, rotating, oscillating, or reciprocating motion these bearings are used. These are also suitable for a wide variety of industrial machinery such as construction and agricultural equipment.

Advantages of Plain Bearings:

There are the following advantages of pain bearings such as;

- Large load carrying surface area.

- The load-carrying capacity is high.

- High tolerance for misalignment.

- It can handle oscillating or reciprocating movements.

Ball Bearings:

These bearings are the most common types of bearings and from inline skates to hard drives, they are found in everything. These types of bearings are usually found in applications where the load is relatively small can handle both radial and thrust loads.

The load is transmitted from the outer race to the ball and from the ball to the inner race in a ball bearing and it only contacts the inner and outer race at a very small point which helps it spin very smoothly since the ball is a sphere. But the balls can deform or squish, ruining the bearing if the bearing is overloaded.

By their circular shape in which many small balls are housed, ball bearings are characterized and while taking both radial and axial loads off a moving part they reduce friction.

Advantages of Ball Bearings:

There are the following advantages of ball bearings such as;

- With a higher dripping point, the bearing uses grease.

- To prevent leaking of lubricants, these are a better sealing shield.

- It has easy bearing replacement and increases motor performance.

- It has a cheaper cost for replacement and in the market, these are easily available.

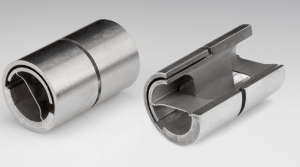

Roller Bearings:

One of the types of bearings that contains the rolling elements either balls or rollers in circular-shaped races is called roller bearing and also known as the rolling-element bearing.

The roller is a cylinder in these types of bearings and to handle much greater loads than a ball bearing this spreads the load out over a larger area. To handle much thrust loading, these are not suitable.

Advantages of Roller Bearings:

There are the following advantages of roller bearings such as;

- For mass production, it is suitable and production efficiency is high, and the quality is stable and reliable.

- As compared to the traditional fluid dynamic bearing the axial size is less.

- The weight is light and the structure is compact.

- The unique bearing design can achieve excellent performance within a large load and velocity range.

Fluid Bearings:

These types of bearings are designed to take the load off a moving part while also reducing friction but they don’t contain rolling elements or moving balls.

They contain liquid and the fluid creates a thin layer to which the moving part is exposed which allows it to bear the load and most fluid bearings contain water or oil and in reducing friction both are effective.

These bearings are classified into two types such as hydrostatic bearings and fluid-dynamic bearings. The fluids usually oil, water, or air rely on an external pump in hydrostatic bearings while to form the liquid into a lubricating wedge against the inner surface fluid-dynamic bearings use rotation.

In high load, high speed or high precision applications that ordinary ball bearings either couldn’t handle fluid bearings are used.

Advantages of Fluid Bearings:

There are the following advantages of fluid bearings such as;

- There is a full film of oil between the bearing and race components so they have very low friction.

- As compared to standard bearings, they have lower wear and longer life.

- Since there is less friction and mainly viscous loss to the oil so it should run cooler.

Magnetic Bearings:

Magnetic bearings use magnetism to lift and bear loads without creating direct contact and to keep the load stable, they require continuous power input.

These types of bearings have the ability to run without lubrication or in a vacuum and have very low and predictable friction. In industrial machines like turbines, motors, and generators they are increasingly used.

Advantages of Magnetic bearings:

There are the following advantages of magnetic bearings such as;

- There is minimal friction and wear from load-bearing elements because of no physical contact between rotating and stationary components.

- These are maintenance-free, reducing initial costs as well as operating and maintenance costs.

- In harsh environmental conditions including extremely low temperatures, zero-gravity, and corrosive environments they can be used.

- It provides precise control of the nominal shaft center under load due to high static stiffness.

Flexure Bearing:

A typical flexure bearing is one part of joining two others and requires repeated bending. The flexure bearing can have an indefinite life with the right materials and bearing design but some materials fail after repeated bending even at low loads.

Its resistance to fatigue is another notable characteristic of this bearing and in the sensitive precision measuring equipment, these bearings are also used.

Advantages of Flexure Bearing:

There are the following advantages of the flexure bearing such as;

- They are inexpensive and simple.

- They have very low friction and are also compact and lightweight.

- Without specialized equipment, they are easier to repair.