Two Way Slab: Its 2 Design Methods, Types and Advantages

The Two Way Slab is generally supported on all sides of walls or beams and while transferring the loads to the walls or beams it twists or bends in both directions.

The slab is known as two way slab when the ratio of the long span is less than 2 and in-floor of multi-story buildings this type of slabs are mostly used.

Under the action of loads, the two way slab will deflect in a dish or saucer-like form and if the slab is not cast monolithically with the supports like walls or beams, corners of the two-way slab lift up.

The main bars are provided in both directions and they are perpendicular to each other in two-way slab and depending upon span, the usual thickness of these slabs is in the range of 100mm to 200mm. For the panel sizes up to 6m x 6m two-way slab is suitable and economical.

Two Way Slab Design Methods:

There are two methods for two-way slab design as given below;

- Direct Design Method

- Coefficient Method

Direct Design Method:

Direct Design Method for two way slab determines or prescribes moments for different parts of the slab panel without the need to conduct structural analysis.

The Procedure of Two Way Slab Design by Direct Design Method:

There are the following steps in this procedure such as;

- Determine slab layout and type and for avoiding excessive deflections and satisfy shear at the interior and exterior columns, choose slab thickness that should be adequate.

- Then choose the direct design method and in the slab calculate positive and negative moments.

- Across slab width, distribute moments and if beams are present, then specify a portion of moments to the beams.

- For moments that found in two previous points, compute reinforcements and check shear strength.

Limitations of Direct Design Method:

There are the following limitations of direct design method such as;

- In each direction, there must be at least three continuous spans and the interior negative moments tend to be too small if there are fewer panels.

- The ratio of longer and shorter spans within the panel must not exceed 2 and panels should be rectangular.

- Successive span lengths must not differ by more than one-third of the largest span length in each direction.

- For slab that subjected to gravity load only, this method is applicable.

Coefficient Method:

In the American Concrete Institute in 1963 to design two-way slabs carried by steel beams, deep beam, or walls this method was provided.

This method employs tables of moment coefficients for different slab edge conditions and these conditions are based on the elastic analysis.

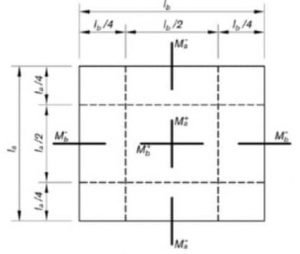

The slab is divided into the middle strip and column strip in each direction according to the coefficient approach and the width of the latter is equal to the one-quarter of the panel width.

Reinforcement Requirements:

During reinforcement detailing, the following consideration provided by ACI Code shall be taken into account;

Placement Sequence;

To the top and bottom of the slab, reinforcement bars for short spans are recommended to be placed closer and in short spans, reinforcements will have greater effective depth.

It needs to be clearly noted and shown in the drawing if special reinforcement placement is considered and this placement configuration should be maintained.

Concrete Cover;

To the surface of reinforcement in slabs minimum, the clear cover is 20mm apart from the condition where the slab is in direct contact with the earth to weather and this is according to the American Concrete Institute ACI code.

Spacing Requirements;

For positive and negative moments in both the middle and column strips, the maximum spacing of reinforcement at critical design sections shall not exceed two times the slab thickness. At any location, the bar spacing shall not exceed 450 mm.

Procedure:

- According to procedures provided determine the thickness of the slab and determine the factored loads.

- By using tables, determine moment coefficients.

- In each direction, compute positive and negative moments.

- Then in the final step calculate the reinforcement area and then the number of bars and their spacing.

Types of Two Way Slab:

There are the following types of this slab such as;

- Two Way Flat Plates Slab

- Two Way Flat Slabs

- Two Way Waffle Plate Slab

- Two Way Slab With Hollow Block

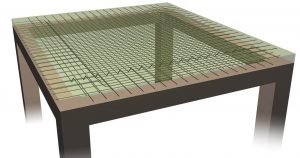

Two Way Flat Plates Slab:

This type of slab is simply a slab of uniform thickness directly supported on columns and for relatively light loads it is suitable.

For spans up to 8m using reinforced concrete and up to 11m with the post-tensioned system, two way flat plates can be used and it is the most economical floor system as the formwork and reinforcement work could be easily done.

For deflection, these plates have low punching shear capacity and low stiffness and to stiffen the free edges and to support the brick walls, beams are provided at the periphery of the slab. In earthquake zones, they are not recommended.

Two Way Flat Slabs:

For the larger loads and spans, the two way flat slabs are more suitable because it has higher shear and flexural strength due to the drop panels or column capitals. Thus for heavier loading and longer span, flat slabs are used and it requires less concrete and reinforcement.

For spans up to 10m and imposed loads up to 7 KN/m2, flat slabs may be used and they are used in spans that are nearly square or square.

Two Way Waffle Plate Slab:

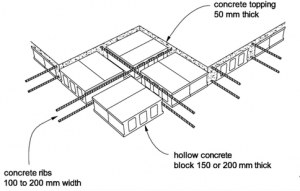

A two-way waffle plate slab is equivalent to a two-way joist system or may be visualized as a solid slab and to decrease the weight of the slab, they are used.

With filler panels over the columns, waffle flat slabs have a square grid of closely spaced joists.

Two Way Slab With Hollow Block:

Advantages of Two Way Slab:

There are the following advantages such as;

- Do not obstruct the reflection of light

- The height of the room is more available in this slab.

- In this slab, a flat ceiling is available because in the middle of the cell there is no beam.

- Increases the beauty of the room.

Disadvantages:

- The design method of this slab is more complex.

- The skilled worker is needed in this.

- There is a relatively high construction cost.