Translucent concrete, Its 8 Manufacturing steps

The translucent concrete has been noted in the architectural press as follows.

University of Houston (Bill Price) has replaced the traditional concrete materials, i.e., fine aggregate, coarse aggregate, and cement, as a binding agent, with glass and plastics of various bonds and sizes together with a transparent glue.

Concrete is generally reinforced with steel, the same purpose he has also looked at using transparent plastic rods. He claims that tests of his initial samples that structurally translucent concrete are just as good as the traditional types but would cost around four times as much.

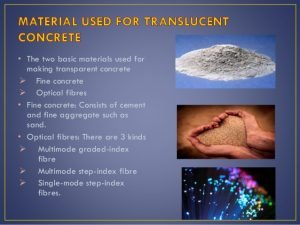

MATERIALS USED

the materials used in translucent concrete

Cement:

Cement is a binder material that hardens and sets after a definite period depending upon its type. Ordinary Portland cement is the most common type used in construction projects.

Fine aggregates:

Fine aggregate (such as sand) is a chemically inert material that fills the voids in coarser particles. Hence it reduces porosity and increases strength. Sand is mostly used for fine aggregate.

Coarse aggregate:

This includes crushed hard basalt chips and crushed granite etc.

Water:

Water should be free from all kinds of alkalies, acids, organic impurities, or oils.

Optical Fibres:

They are consists of three kinds of elements:

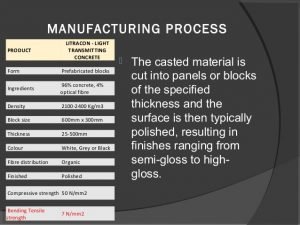

MANUFACTURING PROCESS

Involved are different steps.

1) Moulds of wood or steel are prepared of rectangular size. Clay is placed on the sides for easy demoulding as optical fibers are exposed to the mold of wood or steel.

2) cuts in the optical fibers are such a way that they can be placed perfectly inside the steel or wood mold.

3) The optical fibers are placed layer by layer. Also, holes are driven on wooden or steel plates to let those fibers pass through the plates.

4) The concrete mixture is then poured slowly, slowly with caution so that no disturbance is created to the optical fibers below.

5) void is prevented with the help of vibrating tables.

6) After one day, the mud is pulled off and before the mold is removed and.

7) then, cut the extra-long fibers to the same size as the thickness of the panel.

8) The surface is then polished with the help of polishing paper or sandpaper, resulting in finishes ranging from semi-gloss to high gloss.

PROPERTIES

Properties are shown in the table.

| Product | Light Transmitting Concrete (LiTraCon) |

| Density | 2100- 2400 kg/m square |

| Form | Prefabricated blocks |

| Ingredients | 5% optical fibre and 95% concrete, |

| Block size | 600 mm x 300 mm approximately |

| Thickness | 25-500 mm approximately |

| Colour | grey, black and White |

| Fibre Distribution | Organic matter |

| Finished | Full Polished |

| Compressive Strength | 50 N/mm square |

| Bending Tensile Strength | 7 N/mm square |

APPLICATIONS

Applications of translucent concrete.

- Translucent concrete can act as a building material for exterior and interior walls. The sun’s rays fall on such concrete hit at a lower angle, resulting in bigger light intensity.

- Translucent concrete can be used as a pavement block. Also, translucent concrete gives a shiny appearance during daytime and sunset. It perfectly seems like a concrete block masonry

- translucent concrete can be used as partition walls between the hall and dining room.

- Translucent concrete can be used in handles or can be used in furniture either for decorative purposes.

ADVANTAGES.

- Reduces carbon emission

- It can be treated as high-performance concrete

- Increases aesthetics

- Reduces power consumption.

- Very Low density

- thermal conductivity is Low

- deadweight is reduced

- Increases rate of construction

- Lower handling of cost

DISADVANTAGES

- The very high cost of optical fibers.

- Requires skilled supervision and labor for casting.

- It cannot be used in beams and columns as they do not possess much strength.

- It is dangerous in handling as glass pieces are there.

EXAMPLES OF THE USE OF TRANSLUCENT CONCRETE

Although it is not as widespread, translucent concrete is a few projects that have used it to make remarkable structures.

We Love Cricket