WHAT IS SLUMP TEST? ITS TYPES, PROCEDURE, EQUIPMENTS

Since 1922 slump test has been widely used to check out the concrete workability at the site. This test is also known as the slump cone test. The slump test measures the consistency or workability of concrete. It is used to check the workability of freshly made concrete for the easy placement of concrete. In addition, this test indicates the water-cement ratio and the properties of materials and also admixture, etc. The test is carried out under BS EN 12350-2.

Slump tests can be done on-site to check the concrete mix has expected fluid properties. In addition, this test can be used to measures consistency between the individual batches.

It is a simple and low-cost test prepared at the laboratory or the site during work. It can be carried out from batch to batch to check the workability of freshly made concrete. It is the most straightforward test to check out the workability of concrete.

Workability

The concrete workability is the property of freshly mixed concrete which determines homogeneity, placed, combined, consolidated, and finished’ as specified by ACI Standard 116R-90 or ACI 1990b. The w/c ratio, amount and type of aggregate and cement, admixtures, and weather conditions are the main factors that affect the workability of concrete.

Procedures for slump test [ Step by Step]

The whole concrete slump test is performed under five steps. First, you have to clean all the apparatus that will be used with water and then apply the oil on the surface to make then friction-free.

The sample of slump test:

Concrete having a different mix (M15 or M20 etc.) with a suitable water-cement ratio and can be prepared at the site or casting the six cubes after conducting the slump test.

The sampling and the test are performed under the following rules and laws.

- American Society for Testing and Materials (ASTM) standards are ASTM C 143 or ASTM C143M.

- The American Association of State Highway and Transportation Officials (AASHTO) AASHTO standards AASHTO T119 or AASHTO BS 1881.

- British & European standard BS EN 12350-2.

- Indian standard: IS 1199 – 1959.

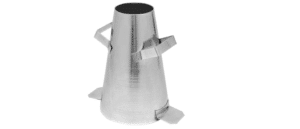

Size of slump cone

The cone both ends are open (Top and bottom). The base diameter is more as compared to the top diameter. The standard size is,

- Cone internal Top diameter is 3.9 inches (100 mm), and the bottom diameter is 7.9 inches (200 mm). The cone height is 12 inches (305 mm).

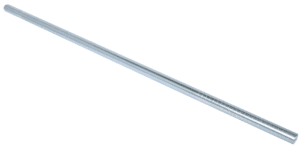

- Metal Tamping road 5/8 (16 mm) in diameter and 2 ft (600 mm) long with bullet-nosed.

- The surface of the whole apparatus must be dry or clean.

Step 1

Place all the apparatus parts together.

- By using a trowel, but the first layer of concrete into the mold.

- Then done tamping on the first layer (25 times) with the help of the rod.

Step 2

The second layer of concrete is added to the mold.

- Again the (25 times) tamping was done with the rod.

Step 3

The third layer of concrete is added after the proper tamping.

- Again 25 strokes were done to do the proper compaction.

- Excess concrete is removed from the above.

Step 4

In four-step, the cone was lifted upward correctly.

- The cone lifting angle must be 90 degrees.

Step 5

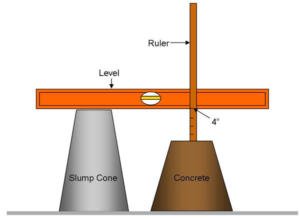

The slump Value was noted on ppaper with the help of measuring tape.

Types of slump test:

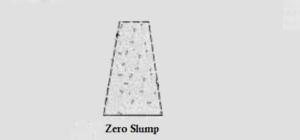

1: Zero slumps:

This test indicates the very low water-cement ratio, which results in dry mixes. This test is mostly used in road construction works.

- A slump occurred when the value of the recession was recorded below 1/4 inch.

- In this, the concrete is very stiff or extremely dry consistency.

- It is defined as Concrete Terminology (ACI 116R-90).

2: True slump:

This measurement is taken from the top of the concrete when the slump cone has been removed. The true slump is considered more desirable as compared to the shear slump.

- This test is mainly used for checking the consistency of lean concrete.

- In true slumps, the concrete subsides shortly and maintains its cone shape.

- More desirable slump.

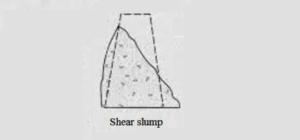

3: Shear slump:

The top portion of the concrete surface slips sideways, and the shear off is a shear slump. If shear is achieved in the concrete, then a sample should be taken and repeat this test.

- The concrete may have a little more water-cement ratio as per design.

- Lake of cohesion of the mix.

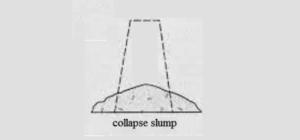

4: Collapsed slump:

This test indicates the water-cement ratio is too high. It means the concrete is high workability and high concrete mix. This slump test is not appropriate.

- High water-cement ratio.

- High workability.

- Low concrete strength.

Equipment’s for slump test:

Mould

The mold shape is in a cone. The cone is known as the Abrams cone or slump cone.

- Slump cone is made of plastic or steel, etc.

- The surface must be dry.

- Friction-free surface.

Tamping rod

Rod is made up of steel.

- 24″ in length and has a diameter of 5/8” diameter.

Baseplate

The base plate may be made of polymer, Aluminum or steel, etc.

- It may be equipped with a holding attachment to lift the plate.

Tape measure

The standard measuring tap is used to take the slump value measurement.

Steel Brush

We use the brush to clear the last remaining concrete left on the mold.

Trowel

This instrument helps to lift the concrete and put it into the mold.

Concrete slump test:

workability slump concrete mix

Very low 0-25mm use dry mix concrete design

Low 25-50 low workability concrete mix design

Medium 50-100 medium workability concrete mix design

High 100-175 high workability concrete mix design

Factors affecting the concrete slump test:

- Mixing, batching, and transporting of concrete

- Temperature of concrete

- Techniques and sampling of concrete slump testing

- W/c ratio of concrete

- Size of aggregate

- The moisture content of aggregates

- Cleanliness of aggregates

- Fineness of materials

- Air content of concrete

Read also:

If you like this shear this information with your friends……

We Love CricketAdd a Comment

You must be logged in to post a comment.

This is a helpful information to me since i’m doing my first year in civil engineering studies and is something we are covering this semester.

thank you so much