Refractory cement

High-temperature masonry Comes from thermodynamically and multiple forms of stable refractory bricks to castable fire cement that is formulated from thermally resistant specialized aggregate materials and clinkers. Conventional cement is often used in the manufacturing of furnaces and fireplaces, but they do not exhibit the requisite thermodynamic stability for direct application to components that will experience significant thermal stress for direct application to components that will experience significant thermal stress or for application within the heating chamber.

Solids routinely contract and expand when subjected to temperature fluctuations, particularly thermally conductive metals. Cement used to adhere to structural metals together in for the sealing of joists and gaskets or the refractory applications and must retain their structural integrity in the presence of continuous thermodynamic stress. While regular (ordinary) cement may expand well in conjunction with other rigid equipment, refractory cement often fails upon contraction due to the deterioration of the binding material or clinker.

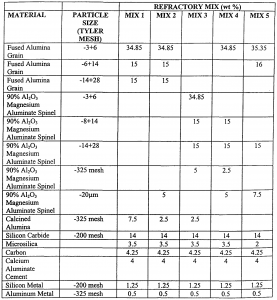

It uses binding materials with improved thermodynamic properties to reduce the risk of mechanical failure. Fused minerals like alumina or aluminum oxide, are used to provide superior temperature resistant properties without reducing the formability of the material and bind coarse aggregate materials. This arrangement enables the fabrication of refractory cement with outstanding thermal resistance and a combination of formability.

Refractory Cement of Materials Consisting

- Calcareous of Materials.

- Aluminous Materials mainly( Al2O3).

- Barium Chloride/Sodium Chloride/Magnesium Chloride/Calcium Chloride.

- A mixture of coarse aggregate and clinker or binder: mineral mixture used as alumina-lime (bauxite-lime) or Clinker is a fused mineral, crushed into a fine powder. It is obtained from aluminous materials. Coarse aggregates are like granular materials which impart some special properties, for example, erosion or oxidation resistance and refractoriness.

- Alumina ceramics, aluminate cement, monolithic fire clay, bricks, and precast shapes.

- Magnesia.

- Reactive magnesia.

- Organic acid.

- Asbestos.

- Burned spinel.

Applications

It is mixed with refractory aggregates such as:

- Bauxite.

- Chamotte.

- Alag.

- Perlite.

- Vermiculite.

- Bubble alumina.

- Tabular alumina.

- White Fused Alumina.

- Brown Fused Alumina.

- Andalusite.

- Sillimanite.

It is can be used in various places. Example:

- Wood burning stoves and Fireplaces where the temperature is very high refractory cement can be used.

- Refractory cement is a good material for the Incinerators patch and Furnace.

- At the time of bonding fire bricks and Setting in firebox chambers, refractory cement can play a good character.

- thermal insulation or Electrical. For providing thermal insulation from any type of heat it can do a better role.

- To seal gas and air leaking fire cement acts well.

Installation technique of Refractory (fire) Cement

- Dry Gunning.

- Wet Gunning or Shotcrete.

- Self-flow Casting.

- Vibration Casting

- Pump Casting.

Exception From normal Formula

Fire cement properties of cement can be imparted to it from non-refractory CaSO4. Refractory cement can be done by the incorporation of a primary fluxing component. This exception can be used as a Structural board, for forming as oil well casing cement and a refractory mass.

Refractory Cement thermo seal

At Mid-Mountain Materials, we provide three distinct fire cement for refractory adhesion applications and thermal insulation. These are optimized to withstand contraction of fireboxes and smoke chambers and thermal expansion, and to provide seals for gas fireplaces and secure adhesion of gaskets, ovens and industrial furnaces and wood stoves. High capacity refractory or fire cement can also provide sufficient resistance to erosive media, corrosive smoke, and thermal spalling, sustaining their mechanical integrity against direct flame impingement.

Mid-Mountain Materials of Refractory Cements

At Mid-Mountain material, we have developed a substantial range of high-temperature moldable materials for domestic and industrial applications. Our thermal sealants have been used to protect standard industrial furnaces and fireplaces alike, with distinct products optimized for a range of temperature bracket requirements.

We Love Cricket