Lintel Beam | 6 Types, purposes & Advantages of Lintel Beam

A lintel beam is a beam placed across the openings like windows, doors, etc in the building to support the load from the structure above, and the ends of this beam are built into the wall and the width of the lintel beam is equal to the width of the wall.

We use lintel above the opening as a simple solution whenever we want to create an opening like doors and windows in the building. To take loads coming from the above wall and transfer its load to the side walls is the main function of the lintel beam.

These beams are rectangular in plan and section, and with different materials, they are constructed.

Purposes of Lintel Beam:

There are the following purposes of lintel beam such as;

- These beams are used to support the walls above the openings like windows and doors, etc.

- As a safeguard of the windows and doors, these beams are provided.

- These beams are provided to withstand the imposed loads coming from above blocks or bricks.

- It is provided to transfer its load to the side walls.

- Sometimes as decorative architectural element lintels are used.

Types of Lintel Beam:

There are the following types of lintel beam as given below;

- Timber Lintel

- Stone Lintel

- Brick Lintel

- Steel Lintel

- Reinforced Concrete Lintel &

- Reinforced Brick Lintel

Timber Lintel:

These are the most seasoned sorts of the lintel and they are used where timbers are accessible like hilly areas but nowadays they are replaced by several modern techniques.

Timber or wooden lintel beam is more cost and less durable and vulnerable to fire and with the help of steel bolts, it is provided by joining multiple numbers of wooden pieces if the length of the opening is more.

It is composed of two wooden pieces kept at a distance with the help of packing pieces made of wood in case of wider walls, and sometimes by the provision of mild steel plates at their top and bottom, these are strengthened.

There are some disadvantages of timer lintel such as;

- It is vulnerable to fire and also less durable.

- Timber lintels tend to be structurally weak and timber is obligated to rot without appropriate ventilation.

Stone Lintel:

This type of lintel beam is mainly used in such areas where the stone is plentifully accessible and thicknesses of these are the most important factor of its design and also provided over the openings in brick walls.

In the form of either one single piece or more than one piece, the stone lintel is provided and the thickness is taken as 4 cm per 30cm length of span and the minimum thickness should be 8 cm as a thumb rule.

Due to the non-availability of other materials for their construction, they are mostly used in mountainous buildings as they weigh too much. These lintels have some problems such as;

- They are not used in buildings where vibratory loads are subjected to the structure due to their weak tensile nature.

- Its transportation is a very complex task and is difficult to deploy them in cities.

- Not able to withstand excessive transverse stress.

Brick Lintel:

With hard and well burnt first-class brick these lintels are constructed and are used when the opening is small as less than 1m with light loadings.

Depending upon the span their depth varies from 10 cm to 20 cm and at end joints, bricks with frogs filled with mortar give more shear resistance.

Steel Lintel:

When the superimposed loads are heavy and the opening gaps are significant then steel lintels can be suitable and are preferable when the depth of lintel plays an essential role.

Steel lintel consists of channel sections and depending upon the requirement, we can use one single section or in combinations.

The steel joist is either embedded in concrete or cladded with stone facing to keep the width the same as the width of the wall when used as one single section while they are kept in position by tube separators when more than one unit is placed side by side.

There are many advantages of steel lintels such as;

- Without the need to change or strengthen steel lintels can be utilized to help heavier loads over more prominent separations.

- To rust, erosion, or distorting these lintels are impervious.

- These lintels are less labor-intensive and more practical.

Reinforced Concrete Lintel:

In reinforced concrete lintel, reinforcement is used to overcome the low workable issue in concrete and these lintels are most commonly used.

For heavy loads and larger spans, they are suitable and for every meter, their thickness is kept around up to 8 cm and can be precast or cast-in-situ. To resist the tensile stress, main reinforcement bars are used at the bottom, and at the ends, half of these bars are cranked.

There are many advantages of this type of lintel beam such as;

- These lintels are strong, rigid, and durable.

- It has fire-resisting properties.

- They are easy in construction and are economical.

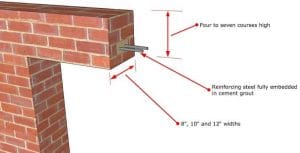

Reinforced Brick Lintel:

When loads are heavy and span is greater than 1m these lintels are used and depth should be equal to 10 cm or 15 cm. As reinforcement, the bricks are so arranged that 2 cm to 3 cm wide space is left lengthwise between adjacent bricks for the insertion of mild steel bars.

Cement mortar is used to fill up the gaps and in every third vertical joint, vertical stirrups of 6 mm diameter are provided and the main reinforcement is provided at the bottom.

Advantages of Lintel Beam:

There are the following advantages of these beams such as;

- They are easy to build and look simpler.

- They are not required to be constructed so firmly because over the ending supports of lintels the excessive load is not applied.

- Frameworks are inexpensive and centering of the lintel is easy.

- If the load is coming uniformly, they can bear a high amount of load.

- They look simple and are delicate.