Grillage Foundation | Types, Design, & 6 Installation Steps

Grillage foundation consists of one, two, or more tiers of beams (regularly steel). To distribute the load over an extensive area, these beams are superimposed on a layer of concrete.

At the base of columns, the grillage foundation is used and used for scaffolds and heavy structure columns piers. The grillage foundation is the most economical in transferring heavy loads from columns to the soil of low bearing capacity.

This foundation includes several layers of beams usually laid at right angles to each other and used to spread heavy loads to an allowable ground bearing pressure from the superstructure.

Steel, precast concrete, or timber are the most common in grillage beams. A grillage foundation is an economical and lighter solution for transferring heavy structural loads to a soil weaker in bearing capacity.

Into the one structure, the grillage connects the whole foundation and contributes to a uniform distribution of the weight of all the piles and houses. As a monolithic reinforced concrete structure, this foundation is arranged most often and by the metal frame like steel grillage foundation.

Types of Grillage Foundation:

Grillage foundation is of two types according to the materials used in construction;

- Steel Grillage Foundation

- Timber Grillage Foundation

Steel Grillage Foundation:

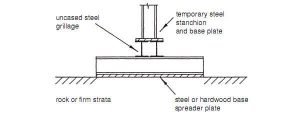

This foundation consists of beams or steel joints provided in single or double tiers and as-rolled steel joist. It is made up of steel beams.

On the outer sides of the external beams, a minimum cover of 10 cm is kept, and also above the upper flanges of the top tier and 15 cm should be the depth of concrete.

We should check that if the compaction is done properly and formed an impervious layer of thickness not less than 15 cm after leveling the base and pouring the concrete. Then with the help of pipe separators, lay the first layer of beams over the concrete bed at a distance of 100mm to 300mm, and between and around the beams of the first tier, pour the concrete.

Then place the second tier of the beam at the right angle to the first tiers and again pour the concrete. Then with the help of a base plate, side angles, and a gusset plate, connect the steel stanchions to the upper tier.

Timber Grillage Foundation:

For heavily loaded masonry walls of timber columns, timber type foundation is provided and is especially useful in waterlogged areas, where the bearing capacity of the soil is very low.

Between the timber joints, there is no concrete surrounded, and the bottom layer of timber planks size is about 20cm to 30cm in width, and 5cm to 7.5cm in thickness and without any gap between them laid side by side.

A timber beam of the same section as that of the wooden post is placed at right angles over the top of the layer and then at right angles to the direction of beams again another layer of planks is laid and maybe 7.5cm to 10cm thick upper layer of planks extending over the entire width of the wall base.

Design of Grillage Foundation:

It is required to calculate the loads and moments from the superstructure for the design of the grillage foundation, and for a suitable allowable ground bearing pressure of the condition, we have to determine the required base area. First, we will find out the numbers and size of each grillage layer by dividing this area, then we have to design the layer that cantilevers from the edge of the layer above.

To resist the bending moments and shear forces, it will determine the beam sizes required, and with the design necessities, the method of construction and loading should be compatible.

Installation of Grillage Foundation:

There are the following steps in the construction or installation of the grillage foundation;

- Firstly, we have to produce and install the framework for solid monolithic grillage.

- The formwork is created from edging boards in the form of rectangular troughs, and its width is equal to the minimum wall thickness of the house, and its height is 1 ft.

- About a 6 to 8 inches gap in between each grillage, it must be set, and we have to set a framework of reinforcement connections using binding wire inside the formwork.

- The same least distance is required from the frame to the side of the formwork, and then with the same binding wire, the reinforcement is linked.

- Next, using the cement mixer, concrete has to be prepared, and in a continuous cycle, it is poured into the formwork. At the height of about 25mm to 30mm, fittings must be placed, and to avoid unwanted cavities, concrete should be carefully poured.

- The surface has to be leveled and left to dry after filling the surface, and the formwork can be removed when it is dried. The foundation is ready.

Suitability:

- This type of foundation is suitable to construct for buildings of light construction materials on weak soils.

- On the construction of the foundation, this foundation is a desire to save up to 30%.

- Do not allow to build the other type of foundation in areas where soil characteristics and conditions of their occurrence weak.

- The load should be expected to be relatively small for the structure.

Advantages of Grillage Foundation:

There are the following advantages of the grillage foundation such as;

- This foundation reduces the heat-evoke of the house.

- If the house is built near highways, it is very actual and reduces the level of the house vibration.

- Contractors can save time using a foundation of grillage because it has a good speed of Installation.

- To avoid poured concrete and saves time with easy Installation, this foundation is used.

- Through minimal disruption of transport infrastructure, this method is cost-effective.

Disadvantages:

- At sufficiently great depth, there is the need for the construction of piles in this foundation.

- In grillage, foundation space under the grillage has to be warmed and filled.