What is Dewatering its Techniques and precautions

Its simplest definition is the removal of water from the working place. This process is used in every industry but is commonly referred to in wastewater and construction when water is separated from solids through various filtering or pumping processes.

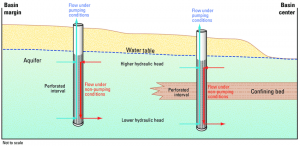

Construction of dewatering is often referred to as unwatering or water control. It involves pumping from sumps or wells to temporarily lower groundwater levels to allow excavations to be made in stable or dry conditions below the natural groundwater level.

Wastewater treatment and dewatering are the part of the process whereby it is converted from a liquid to a solid product, and sludges are reduced in volume. Biosolids dewatering typically occurs when storage and transportation costs for large volumes can be reduced or when the material is destined for landfills. The biosolids dewatering process affects not only the volume but also the odor levels and nutrients of the material.

Dewatering Techniques

Construction methods refer to deep wells, bypass, well points, and flood control. In deep wells and wellpoint, submersible pumps are installed in a drilled well shaft, while in flood control, pumps and bypass are placed in the area that needs to be dewatered. Let’s review all techniques.

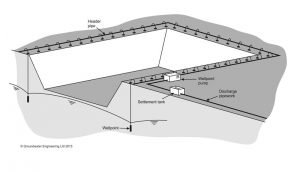

Wellpoint’s

Wells are drilled around the excavation area with connecting submersible pumps installed in the good shaft. These pumps are installed to a header pipe, allowing the groundwater to be drawn up through pumps into the Wellpoint’s and then discharged.

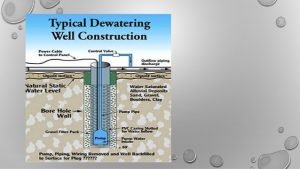

Deep wells

One or several individual wells are submersible pumps, and drilling is placed in each shaft. It is the best technique suited for the deep foundation or excavations where large water volumes need to be discharged from the working place.

Bypass dewatering

When needed maintenance of sewer lines, the sewage flow is around pumped the damaged pipe section using dewatering pumps. The pumps are connected upstream of the maintained pipe section. The bypass technique is also common in construction projects and canal irrigation.

1: Flood control

This technique refers to all methods used to prevent harmful effects of flooding or reduce from, for example, heavy rainfall and stormwater. For construction, mine work, or tunneling, site managers need to be prepared for potential site flooding, keeping pumps that can move the high-level water volumes against low head pressure nearby.

2: Tunneling dewatering

It is used for the Tunnel constructions are multiple worksites where many variables need to be considered. Significant volumes of water from the construction site need to be removed to prevent flooding of the work area or stabilize the ground. Tunnel drilling equipment and boring machines require a reliable supply of cooling water, which must be recovered, treated, and extracted after use. Many require dewatering pumps for the Tunneling projects on site.

Dewatering Methods

Many methods can do construction of dewatering from trenches or open excavation. However, the most simple method of all is the gravity drain. Gravity drain using drainage channels carrying away discharge water from the worked area.

Other possible ways are water pumping, siphoning, and large construction machinery buckets to dump water and scoop from the selected area. Earth channels used for dewatering could also be protected with additional protection, and ditch linings should be placed to minimize erosion and reduce water velocities. It is recommended to build riprap prevention protection with geotextile to prevent additional erosion at the discharge point of water.

Dewatering Precautions

Activities of Dewatering must be done properly to avoid eroding the soil on the project site. Precautions are also important to choose the best location for discharge the water, even when you might be far away from catch basins or water bodies. Multiple tools can be used to sediment from the pumped water remove, such as bags.

- Water should not be pumped directly into slopes.

- Activities of Dewatering should be directed to a wooded buffer, if available on the market.

- Precaution is important to discontinue it and pay special attention if the area shows signs of erosion or instability.

- Channels used for dewatering must be better and stable if they have been protected with vegetation or grass.

- We should avoid water under heavy rains because the rate of infiltration is minimal, and water will move slowly, or just the dewatering process will not function.

- Never discharge water that has been contaminated with chemical products or oil, grease indirectly. In such instances, an oil/water separator may be necessary.

- Additional requirements and permits might be necessary from the federal agencies or state and local.

- Precaution of water removing is important to understand the water table conditions in the working area. Maybe the underground water is always near the surface, so it isn’t easy to plan your work.

- Sump pump techniques are commonly used for dewatering, but they can handle only a small water discharge volume.