Bolts and Screws: their 5 Types, Advantages, & Difference

The bolts and screws are two unique fasteners with their own unique applications and usually, bolts and screws both look similar and have similar characteristics.

Typically with the use of a nut, the bolts are used to assemble to unthreaded objects and the screws are used to assemble objects with threads as the explanation of Machinery’s Handbook.

Bolts:

Bolts are externally threaded fastener which is used to position and hold two or more components together and for high duty applications, bolts are generally used along with washers and nuts.

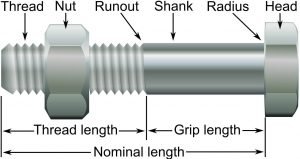

With screw threads along a portion of bolt length it consists of a head and a cylindrical body and to match those of the bolt, the nut is a member of the pair having internal threads. To prevent loosening and crushing washers are often used.

As compared to screws and other fasteners, bolts provide the best holding strength and also provide an unparalleled level of holding power. For their installation, they require a nut and a washer and the nut secures the bolt in place while the washer helps to spread the load over a larger surface area which reduces the wear and tear.

The bolts come in many sizes and types and with several materials ranging from metal and wood to concrete, they are also usable.

To remove or install, a bolt requires a handheld or pneumatic wrench and bolts can be easier to remove as compared to screws. It makes your work easy because a pneumatic wrench provides much more torque than a handheld tool.

Types of Bolts:

There are the following types of bolts such as;

Anchor Bolts:

These bolts are designed to be used to attach a structural member or component to a poured foundation or concrete slab and by the use of a drilling operation to create a channel into which the anchor bolt may be inserted & these bolts may be attached after the concrete has cured.

Double End Bolts:

One end of these bolts is threaded to support a nut while the other end is designed to be threaded into a suitable hole that has been tapped with a mated thread. These bolts are similar to that of the threaded rod but it may be threaded differently on each end and is traditionally not threaded over the entire length of the stud.

Blind Bolts:

In cases where the application does not allow access to both sides of the bolt to tighten or torque the bolt then blind bolts allow for the use of a fastener.

Machine Bolts:

These bolts are similar to hex bolts and used to fasten together two pieces of material. They are not designed with a washer-bearing surface on the underside of the head and they will not have a chamfered point. In both hex head and square head options, they are typically available.

U-Bolts:

These bolts contain a threaded portion on each end of the bolt on to which a mounting plate bracket and attachment nuts are placed and these bolts are in the shape of the letter U. From supporting pipe to automotive use on drive shafts and exhaust systems these bolts are used.

Advantages of Bolts:

There are the following advantages of bolts such as;

- The bolts have an excellent life cycle.

- It is simple to install and uninstall bolts.

- Corrosion-resistant.

- They do not require heat treatment.

- They are inexpensive and easily available.

Screws:

Screws are used to position and hold two or more components in one place and it is a type of externally threaded fastener.

Into the tapped hole, a screw is usually installed and it does not need nuts because they become secure by being tightened into the hole with a screwdriver which fits into the drive recess and they are shorter than the width of the material they are being screwed into.

The screws are available in a variety of sizes and types for wood, metal, concrete applications, and drywall. These are designed to be self-tapping but you may still want to drill a pilot hole in many cases and this process is a little less time-consuming if you drill all your pilot holes at once.

For lifting heavy objects and to tighten things, screws are used and mostly used to hold things together.

Types of Screws:

There are the following types of screws such as;

Wood screws:

Wood screws are used to connect two or more solid wooden objects and they are not made of actual wood and for woodworking applications, these screws have a sharp point that is able to dig into the wood making them highly useful.

Machine Screws:

These screws are used in machining applications and there many different types of machine screws. To hold heavy-duty metal objects together these screws are used and normally machine screws can have a diameter up to 0.75 inches.

Lag Screws:

These screws are essentially jumbo-sized wood screws coated with zinc and also known as lag bolts or coach bolts. To protect them against rust and corrosion a zinc layer is applied to lag screws and companies typically perform electroplating or hot-dip galvanization to apply the zinc.

Sheet & Metal Screws:

These screws are designed to be driven into sheet metal and also be used on other materials like wood but for sheet metal, they are primarily used.

Twinfast Screws:

These screws have a unique design consisting of two threads rather than just one and they can be driven into objects twice as quickly. For other applications besides the installation and hanging of drywall, these screws are also used.

Advantages of Screws:

There are the following advantages of screws such as;

- They resist the problem of loosing and are very strong.

- They are strong enough to hold things together.

- They prevent moisture and are highly resistant to rust.

- The screws are easy to remove.

- These are specially designed to use on sheet metal, wood, concrete, and drywall, etc.

Difference between Bolts and Screws:

For holding things together or attaching to other things, the fastener is used as a restraint and the main physical difference between bolts and screws is that bolts contain shanks without threads while screws are entirely full of threads.

A better interpretation of the differences between bolts and screws is that screws are normally used with tapped holes while bolts are always fitted with nuts.

We Love Cricket