Biodiesel Production – its 6 Steps, Materials and Advantages

Biodiesel production is done through a chemical process in which the glycerin is separated from the fat or vegetable oil and this chemical process is called transesterification.

Biodiesel is made from an increasingly diverse mix of resources such as soybean oil, recycled cooking oil, and animal fats, and in existing diesel engines without modification, it can be used.

To help meet transportation fuel needs, biomass can be converted directly into liquid fuels and is called biofuels and there are two most common types of biofuels in use today are ethanol and biodiesel.

For diesel engines, biodiesel is an alternative fuel and is produced by chemically reacting a vegetable oil or animal fat with alcohol like ethanol or methanol.

Oil + alcohol → biodiesel + glycerin

Materials for Biodiesel Production:

There are the following materials used in the biodiesel production as given below;

Vegetable Oils & Animal Fats:

In biodiesel production, the vegetable oils and animal fats are used and from virtually any source these can come. These products consist of chemicals known as triglycerides, so from soybean oil, canola oil, beef tallow, and pork lard biodiesel can be made, and even exotic oils as avocado oil or walnut oil are used.

Cooking Oil or Waste Oil:

In biodiesel production, cooking oil or waste oil can be used and for biodiesel production, these oils present special challenges because they contain contaminants such as water, meat scraps, and breading. Before the oil is converted to biodiesel that must be filtered out.

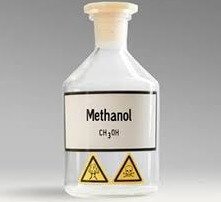

Methanol:

In biodiesel production, methanol is the most common alcohol which is used and it is very toxic, and swallowing as little as a spoonful can cause death or blindness. From breathing methanol vapors or absorbing methanol through skin contact dangerous exposure can also occur and it is sometimes called methyl alcohol.

Process of Biodiesel Production:

There are the following steps in the process of biodiesel production as given below;

- Mixing of Alcohol and Catalyst

- Separation

- Alcohol Removal

- Glycerin Neutralization

- Methyl Ester Wash

- Product Quality

Mixing of Alcohol and Catalyst:

The catalyst is typically sodium hydroxide or potassium hydroxide and by using a standard agitator or mixer it is dissolved in the alcohol. Then the alcohol/catalyst mix is charged into a closed reaction vessel and oil or fat is added, and to prevent the loss of alcohol, the system from here on is totally closed to the atmosphere.

To speed up the reaction, the reaction mix is kept just above the boiling point of the alcohol around 160 °F and general reaction time varies from 1 to 8 hours. To ensure total conversion of the fat or oil to its esters, excess alcohol is normally used, and to monitor the amount of water and free fatty acids in the incoming oil or fat care must be taken. It may cause problems with soap formation and the separation of the glycerin by-product downstream if the free fatty acid level or the water level is too high.

Separation:

Two major products exist when the reaction is complete such as biodiesel and glycerin, and each has a substantial amount of the excess methanol. At this step, sometimes the reacted mixture is neutralized and the glycerin phase is much denser than the biodiesel phase. A centrifuge is used to separate the two materials faster in some cases.

Alcohol Removal:

The excess alcohol in each phase is removed with a flash evaporation process or by distillation once the glycerin and biodiesel phases have been separated. The alcohol is removed and the mixture neutralized before the glycerin and esters have been separated in other systems.

The alcohol is recovered using distillation equipment and is re-used and to ensure no water accumulates in the recovered alcohol stream, care must be taken.

Glycerin Neutralization:

The glycerin byproduct is sent to storage as crude glycerin and it contains unused catalyst and soaps that are neutralized with an acid. In some cases for use as fertilizer, the salt formed during this phase is recovered and the salt is left in the glycerin in most cases.

To produce 80% to 88% pure glycerin water and alcohol are removed and then as crude glycerin it is ready to be sold. The glycerin is distilled to 99% or higher purity and sold into the cosmetic and pharmaceutical markets in more sophisticated operations.

Methyl Ester Wash:

The biodiesel is sometimes purified by washing gently with warm water to remove residual catalyst or soaps, dried, and sent to storage once separated from the glycerin. This step is unnecessary in some processes and this is normally the end of the production process resulting in a clear amber-yellow liquid with viscosity.

In some systems to produce colorless biodiesel, biodiesel is distilled in an additional step to remove small amounts of color bodies.

Product Quality:

To ensure it meets any required specifications, the finished biodiesel must be analyzed using sophisticated analytical equipment.

To ensure trouble-free operation in diesel engines the most important aspects of biodiesel production are;

- Complete reaction and removal of glycerin.

- Removal of catalyst and removal of alcohol.

- Absence of free fatty acids.

Advantages of Biodiesel:

There are the following advantages of biodiesel such as;

- Unlike petroleum-based diesel, biodiesel fuel is a renewable energy source.

- As compared to petroleum diesel, it is less polluting.

- It extends the life of catalytic converters due to the lack of sulfur in 100% biodiesel.

- With other energy resources and oil, it can be blended.

- In existing oil heating systems and diesel engines, biodiesel fuel can be used.