What is sandblasting

A process is known by several names like bead blasting and abrasive, media blasting. We know sandpaper is used to rub against a surface and abrasive. Doing so removes something like paint or it makes the surface smoother. When we have to sandblast, we use air to force an abrasive toward the surface of a work item. We do this to remove smooth, engrave, debris, and so much more.

Cabinets

There are blasting systems and blasting rooms that don’t require a cabinet but for our discussion, we will focus on blasting done inside a cabinet. An abrasive blasting cabinet is generally a leak-proof container. The cabinet is designed to contain the blasting system, workpieces, and of course the abrasive media. Blast cabinet design is most important. Some cabinets are steel and some are plastic. Many have pop-riveted legs or bolt-on. Others have steel doors, some have plastic doors.

Blasting System

There are two basic means of blasting: siphon and pressure. There are variations in the term siphon and sometimes you’ll hear it called gravity fed. For our discussion, we will use the term siphon fed.

Siphon Fed

Most internet definitions specify a siphon fed as a device. In most circumstances, it’s a tube that can move liquids and air from one container to another using a combination of atmospheric pressure and gravity. The reality in abrasive sandblasting is that a siphon feed sandblaster isn’t siphoning anything. The name is familiar and stuck. Instead, there are a few physics principles at work. After all, when we talk about “what is sandblasting” we are really talking all about abrasive media (chemistry) and the action of the sandblast gun(physics).

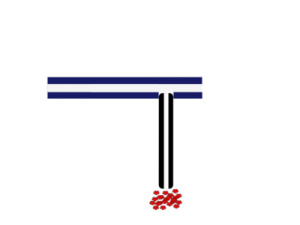

Airflow

Airflow crude shapes represent a nonpressure sandblast gun. The air moves into the system and it moves the pickup tube across an area that connects. The pickup tube is a special device that sits within the connections to the abrasive sandblasting gun and abrasive media. It is specially constructed to allow media to airflow and flow up in and around it. detail Enough will be provided to give a basic understanding of the process.

Pressure Blasting

This system provides a more intense blast stream over a siphon system. And we expect that with a name like a pressure blasting system. The difference key is that with pressure blasting systems we normally look at a pressure vessel. The vessel is fed air from a compressor until a predetermined level of pressure blasting system.

The release the air within the vessel and the user opens a valve. and Finally when the valve is opened the vessel the air inside the vessel fed and the media in the vessel both leave at a very high velocity. An abrasive particle carries very high kinetic energy. a high velocity, Simply put, the high energy particle impacts a surface and can do more work.

Abrasive Media

Abrasive media Isn’t it just sand in a sandblaster? It is Absolutely wrong. The sand was used many decades before, hence the most familiar name “sandblasting”. But do not use sand when sandblasting. It is a cheap means of sandblasting, but there are serious health risks associated with sandblasting with sand.

Risk Reduction

With many abrasive media and safer affordable, we wanted to get proper safety out in front and be clear about knowing some of the risks. We take care to instruct the world safer. Do Not media in a blasting environment is 100% safe. Read Always all warnings. respect the equipment and media safety data sheets for your media in use.

Better Alternatives

There is a vast assortment of abrasive media such as aluminum oxide, and many more, glass beads, garnets.For now, we are simply introducing the concept of abrasive media sand. Earlier on we used the terms bead, shot blasting, and media. Remember that these are just names applied to the process itself or machine.

We Love Cricket