What is Sedimentation Tank? its 5 Types, Advantages & Disadvantages

A sedimentation tank is a structure which removes the suspended particles present in the water wastewater is filled and stored for some time.

At the bottom of the tank, these particles may settle and by using scrapers they are removed. The suspended particles settle at the top of the tank if they have low specific gravity than water.

A sedimentation tank is a component of a modern system of wastewater treatment or water supply and also provides some degree of purification because a sedimentation tank allows suspended particles to settle out of water or wastewater as through the tank it flows slowly.

Types of Sedimentation Tank:

There are many different types of sedimentation tanks as discussed below;

- Rectangular Tanks

- Circular Tanks

- Hopper Bottom Tanks

- Fill & Drawn Sedimentation Tank

- Continuous Flow Tank

Rectangular Tanks:

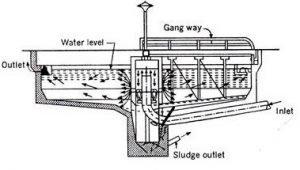

Rectangular tanks consist of a large number of baffle walls and are rectangular in plan. The function of the baffle wall is to prevent short-circuiting and to reduce the velocity of incoming water to increase the effective length of travel of the particle.

With channel type inlet and outlet extending on the full width, this type of sedimentation tank is generally provided and like a hopper sloping towards the centre where sludge pipe is provided, the floor between two baffles is made. By operating the gate valve, the sludge is taken out through a sludge outlet under hydrostatic force.

These tanks are used widely and are mostly preferred as sedimentation tanks. In the case of a rectangular sedimentation tank, maintenance cost is low and for large capacity plants, they are also suitable.

Circular Tanks:

In plain sedimentation, these are generally not used but in sedimentation, with coagulation, they are mostly used.

On the basis of the flow of water there are two types of circular sedimentation tanks;

- Radial Flow Circular Tank:

Through the central inlet pipe placed inside the deflector box the water enters this tank and the deflector box deflects the water downwards. Then through the holes provided in the bottom sides of the deflector box, it goes out, and towards the circumference of the tank, the water flows radially from the deflector box where an outlet is provided on the full periphery.

By scrapper which continuously moves around the floor at a very small velocity, the sludge is removed and the maximum velocity of the raking arm does not exceed 4.5 m/hr.

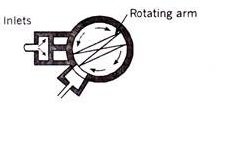

- Circumferential Flow Circular Tank:

Through two or three vertical slits, water enters the tank, and to move water along the circumference of the tank, there is one rotating arm in the tank.

To allows its suspended impurities to settle in the tank water moves at a very low velocity and from a sludge outlet that can be removed.

The clear water is drawn over a small weir-type outlet and the length of this outlet weir should not exceed 1/8th circumference.

Hopper Bottom Tanks:

In these tanks, water flows upward and downward and these are vertical flow tanks. From the top of the deflector, box water enters in these tanks and the water reverses its direction and starts flowing upward around the deflector box after flowing downward inside the deflector box.

The suspended particles having specific gravity more than one cannot follow the water at the time of reversing its direction and settle in the bottom from where under hydrostatic pressure they are removed through the sludge outlet pipe.

To collect the clear water, rows of decanting channels are provided at the top, and water is taken out from the outlet channel provided on one side of the tank after flowing in the channel. In sedimentation with the co-angulation process, these tanks are mostly used.

Fill & Drawn Sedimentation Tank:

In this type water from the inlet is stored for some time that maybe 24 hours and the suspended particles are settled at the bottom of the tank at that time. The water is discharged through the outlet after 24 hours.

Then the settled particles are removed and this action requires 6 to 12 hours so, in the case of fill and draw-type sedimentation tank, one complete action of sedimentation requires 30 to 40 hours.

Continuous Flow Tank:

The water is not allowed to rest in this case and with a very small velocity, flow always takes place. The suspended particles are settled at the bottom of the tank during this flow and this may be in the vertical or horizontal direction.

Advantages of Sedimentation Tank:

There are the following advantages of these tanks such as;

- It is low-cost and simple water pre-treatment technology.

- It has low operating costs and handles a wide range of flows.

- To settle out suspended solids, the coagulants reduce the time required.

- It has high clarification efficiency and easy sludge removal properties.

- For plants with constant flow rates and quality, it is best suited.

- For free or at a low cost, natural coagulants can sometimes be obtained.

Disadvantages of Sedimentation Tank:

There are the following disadvantages such as;

- To protect against freezing in a cold climate it needs covering units.

- The mechanical drive unit and shaft bearings unit require frequent maintenance.