Fly Ash Bricks – Its 4 Manufacturing Steps, Uses & Advantages

Fly ash bricks are used for the construction of brick masonry structures and are hi-tech well-improved quality bricks and also used as a replacement for normal clay bricks.

Fly ash bricks are cast in molds and are always of uniform shape and also lighter in weight. As compared to clay bricks, these bricks are less costly and these bricks are made of waste materials that come from the combustion of coal.

Fly ash bricks are better than clay bricks and are environmentally friendly because maximum constituent is ash and also fly ash bricks have greater strength.

Fly ash bricks have high fire insulation, high strength, uniform sizes for better plaster & joints, and lower water penetration and before use in masonry construction, these bricks do not require soaking.

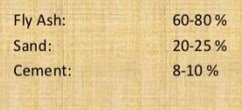

Composition of Fly Ash Bricks:

There are the following compositions of these bricks such as;

- Fly Ash which is the primary ingredient.

- Cement to increase bonding and strength.

- Sand or Stone dust as fine aggregate.

- Water.

Sources of Fly Ash:

The power plants are based on 72% of coal and annually these power stations generate nearly 40 million tones of fly ash.

Fly ash carries Co2 which is emitted from thermal power plants and industries using coal as fuel emits unwanted ash and smoke, from which fly ash is manufactured.

By using the cyclone converter, they separate the fly ash in all the power plants and industries, and then for the manufacture of bricks, this fly ash is used as a raw material.

Manufacture of Fly Ash Bricks:

There are some steps in the manufacturing process of fly ash bricks such as;

- Fly ash bricks are slow setting pozzolana cement mix and the manufacturing process is the same as making cement in cement factories whereas the limestone and clay are burnt with gypsum and coal.

- Then it is mixed and ground to cement and the mixture gives slow setting pozzolana cement when hydrated lime powder and gypsum are mixed and ground in a pan. There is also fly ash which is burnt clay particles obtained from burning coal in fly ash mix.

- Then in the hydraulic machine, the mix is pressed at low pressure at low moisture content which is particularly designed to give high-pressure load at a slow rate in the order of 350 kg/sq.in.

- Withholding the pressure for the desired time at this the rate of pressure gives the ultimate strength to fly ash bricks.

General Characteristics of Fly Ash Bricks:

There are the following characteristics of these bricks such as;

- 230 x 110 x 70 is the standard size of the brick.

- As per IS 12894-2002, the bricks are manufactured and tested.

- In shape, size, and color these bricks are sound, compact, and uniform and with sharp and square corners, smooth rectangular faces of the bricks are accompanied.

- From visible cracks, warpage, flaws, and organic matter they are free.

- On an average compressive strength is 7.5 N/mm2.

Uses of Fly Ash Bricks:

For the construction of various types of buildings, these bricks are used such as;

- In Factories

- In Warehouses

- In Power plants

- In Homes &

- In High rise structures

Advantages of Fly ash Bricks:

There are the following advantages of these bricks such as;

- For construction, they have high strength which is their primary benefit to be used.

- The plaster consumption is minimized compared to clay bricks due to uniform size and thickness of joints and saving cement to the extent of 25 percent to 30 percent.

- There is no dampness in walls due to lesser water absorption.

- Without the basecoat of plaster, the gypsum plaster of Paris can be applied directly.

- As compared to clay brick wastage is very less.

- There is a high concentration of calcium oxide in it so the bonding between the bricks is excellent.

Disadvantages of Fly ash Bricks:

There are the following disadvantages of these bricks such as;

- Slower strength gain and seasonal limitation.

- Increased need for air-entraining admixtures.

- By higher proportions of fly ash increase of salt scaling produced.

We Love Cricket